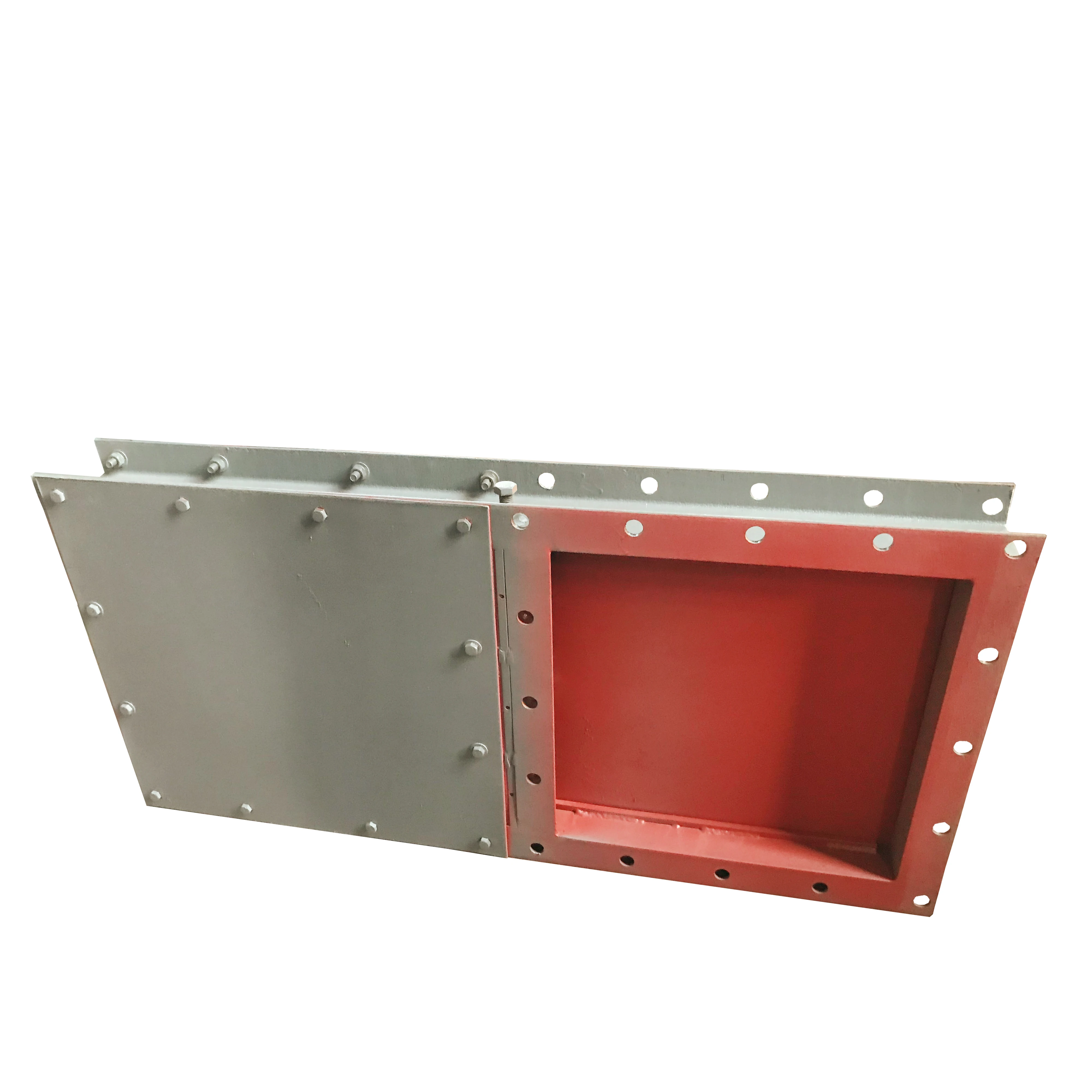

Ideal for handling dry bulk material in gravity flow, dilute phase or dense phase pneumatic conveying applications. Ever Lucky slide gates are designed and engineered with two main principals in mind:

1. extend the service life of the Valve

2. perform maintenance without taking the valve out of line.

Ever Lucky valves serve many industries including chemical, cement, coal, food, frac sand, grain, minerals, petrochemical, pharmaceutical, plastics, polymer, rubber and mining.

The sliding gate valves help control gravity batch unloading when handling dry free flowing materials.powder, pellets, and granules,aggregates, clinker, coal, frac sand, fly ash, gravel, sand and whole grains