Low Energy Consumption Dust Collector Cyclone Separator

- Brand:

- HAINA

- Place of Origin:

- Jiangsu, China (Mainland)

Basic Info

Model No.: xtd

Product Description

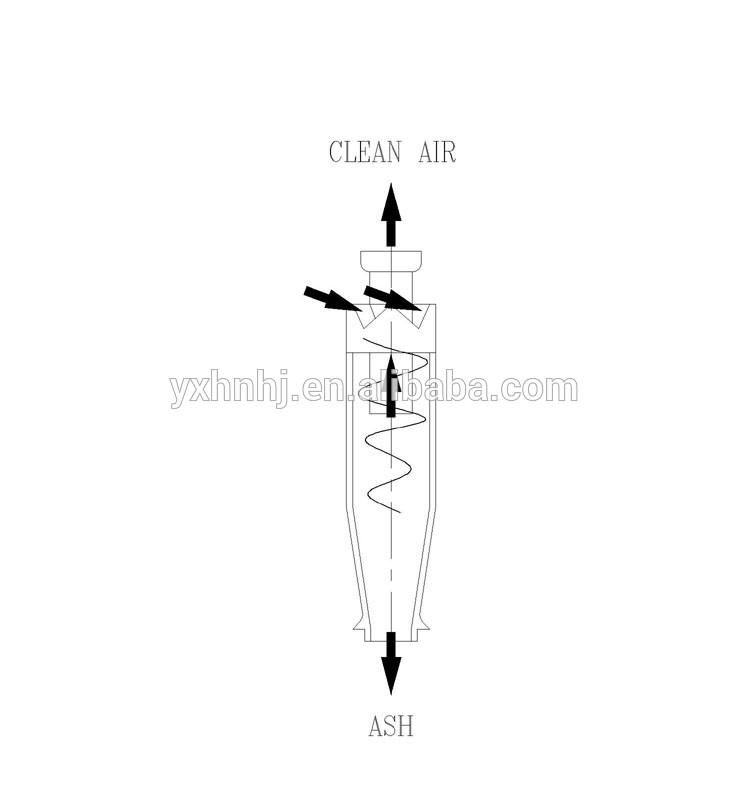

Single cyclone separators

They create a dual vortex to separate coarse from fine dust. The main vortex spirals downward and carries most of the coarser dust particles. The inner vortex, created near the bottom of the cyclone, spirals upward and carries finer dust particles.

Multiple-cyclone separators

Multiple-cyclone separators consist of a number of small-diameter cyclones, operating in parallel and having a common gas inlet and outlet, as shown in the figure, and operate on the same principle as single cyclone separators creating an outer downward vortex and an ascending inner vortex.

Multiple-cyclone separators remove more dust than single cyclone separators because the individual cyclones have a greater length and smaller diameter. The longer length provides longer residence time while the smaller diameter creates greater centrifugal force. These two factors result in better separation of dust particulates. The pressure drop of multiple-cyclone separators collectors is higher than that of single-cyclone separators, requiring more energy to clean the same amount of air. A single-chamber cyclone separator of the same volume is more economical, but doesn't remove as much dust.Cyclone separators are found in all types of power and industrial applications, including pulp and paper plants, cement plants, steel mills, petroleum coke plants, metallurgical plants, saw mills and other kinds of facilities that process dust.

Secondary-air-flow separators

This type of cyclone uses a secondary air flow, injected into the cyclone to accomplish several things. The secondary air flow increases the speed of the cyclonic action making the separator more efficient; it intercepts the particulate before it reaches the interior walls of the unit; and it forces the separated particulate toward the collection area. The secondary air flow protects the separator from particulate abrasion and allows the separator to be installed horizontally because gravity is not depended upon to move the separated particulate downward.

Haina develops the latest Dust Collector Cyclone. High-quality ceramic materials, machinery processing are chosen to fire the cylone through professional pusher kiln sintering.

In terms of craftsmanship, we abandoned the previous manual shaping way, but using mechanical processing instead. The whole cyclone is extruded by model vacuum technology. The three major parts are made as a whole, which avoids air leakage and docking at connection points, and guarantees the effect of the cyclone;

In terms of overall quality, mechanical processing of cyclone ensures the distribution angle and direction angle of cyclone guide vane are even. Since the gas treatment of every cyclone is the same, the gas can be evenly allocated when using the cyclones in parallel that ensure the effectiveness of the Dust Collector cyclones

In terms of wear resistance, compared with manual processing, the cyclone after vacuum extrusion have greater compactness and even wall thickness; thus greatly improve wear resistance of the cyclone

In terms of corrosion resistance, the glaze used on the cyclone adopts international chemical spray glaze, which makes it smooth. It has not only stable chemical properties, but also excellent acid-proof alkaline, high-temperature resistance and abrasion resistance

Haina owns the whole assembly line of the ceramic cyclone processing including production, sintering, and glazing. The daily production increased 5 times than ever before that can satisfy the requirements of customers. Welcome to inquire and negotiate.

Q: Are you trading company or manufacturer ?

A: We are manufacturer.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is one month if the goods are not in stock, it is not only according to the quantity, but also how big the project it is.

Q: Do you provide samples ? is it free or extra ?

A: No, we manufacture equipment which is specially designed for specific customers.

Q: What is your terms of payment ?

A: 30% T/T in advance ,60% before shippment. Another 10% after the device have operated for one month.

If you have another question, pls feel free to contact us as below:

Product Categories : Cyclone

Premium Related Products