Desulfurization System Used Tube Type Drift Eliminator for Cooling Tower

- Packaging:

- The drift eliminator is seperately transported, regular case would be used.

- Brand:

- HAINA

- Place of Origin:

- Jiangsu, China (Mainland)

Basic Info

Model No.: ME

Product Description

Drift Eliminator is the key equipment in the FGD process, it must meet different requirements of operating conditions parameters of the flue gas desulfurization system from design to manufacturing. The best way is to design highest value of parameters into the worst operating conditions.

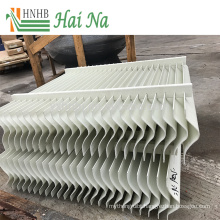

The area of the defogger is calculated to be 1.4 times than theoretical optimum value, since it is the basis of defogging efficiency. Generally, it is showed in the form of type of blades (two or three channels), width of blade (or Flow length) and the number of blade layout.

Drift eliminator is very important. When processing water is balance, the optimum setting of flushing method affects the flushing efficiency directly (including flushing starting procedure, water pressure settings, nozzle type, layout and etc.), the flushing effect directly affects the flushing efficiency of the demister as well.

Critical flow rate is the basis of the entire flue gas desulfurization process to caculate the minimum efficiency of eliminator. optimize the design to minimize the project cost; demister operating at critical flow rate conditions, Water load, easy to carry with water secondarily.

Tube Type Eliminator

Tube type eliminator is installed under the first layer eliminator. It removes large droplets effectively, especially those more than 400-500um, reduces the risk of blockage of the eliminator and prevents most of the slurry carrying with gypsum solids from entering the eliminator directly. The flue gas flow is very uneven within scrubber, eliminator can play the role of uniformizing flue gas. It is no need to add flushing water system.

If tube type eliminator is used in combination with roof type Mist Eliminator and flue type mist eliminator. The demister is more efficient.

Flue gas separates droplets away under the action of inertia force and gravity when passing bending channel of the mist eliminator. Then desulfurized flue gas flows through mist eliminator in a certain speed and changes running direction quickly and continuously. Droplets in the flue gas are captured while crashing into mist eliminator blades under the action of centrifugal force and inertial force. They gather and form into a stream and then drop back to the slurry pool under gravity. Finally gas and liquid are separated, and the flue gas which flows through the demister is discharged after meeting the standard of mist removal. Demisting efficiency of mist eliminator increases as the air velocity gets higher.

1.Large areas, high efficient, low pressure drop.

2.Compact structure,high utilization of flow area.

3.Reasonable layout of washing system, non clogging and scaling under the high dust concentration situation.

4.Safe assembly form, high temperature flue gas shock resistance, uneasy to be ruined.

5.high antioxidant capacity of modified materials,long service life.

6.Esay installation, maintenance and replacement.

Product Categories : Mist Eliminator

Premium Related Products