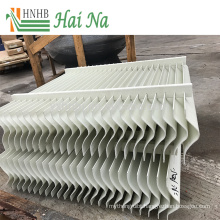

Various Types Cooling Tower Demister Drift Vane Pack Mist Eliminator

- Packaging:

- Regular cargo will be used; Apply to drift eliminator.

- Brand:

- HAINA

- Place of Origin:

- Jiangsu, China (Mainland)

Basic Info

Model No.: ME

Product Description

Flue gas separates droplets away under the action of inertia force and gravity when passing bending channel of the Vane Pack Mist Eliminator. Then desulfurized flue gas flows through Mist Eliminator in a certain speed and changes running direction quickly and continuously. Droplets in the flue gas are captured while crashing into mist eliminator blades under the action of centrifugal force and inertial force. They gather and form into a stream and then drop back to the slurry pool under gravity. Finally gas and liquid are separated, and the flue gas which flows through the demister is discharged after meeting the standard of mist removal. Demisting efficiency of Drift Eliminator increases as the air velocity gets higher.

The high flow velocity and the large inertia force acting on the droplets are conducive to the separation of gas and liquid. However, flow velocity improvement will increase system resistance and energy consumption. The increase of flow velocity has certain limits, because over-high flow velocity will bring water. It may reduce demisting efficiency of the drift eliminator. The highest flow velocity of flue gas with no secondary water when passing through the cross-section of eliminator is always defined as the critical flow velocity. The velocity has relation with the structure of mist eliminator, the water load of system, flow direction, arrangement form of drift eliminator and other factors. Flow rate is always selected between 3.5~ 5.5 m/s.

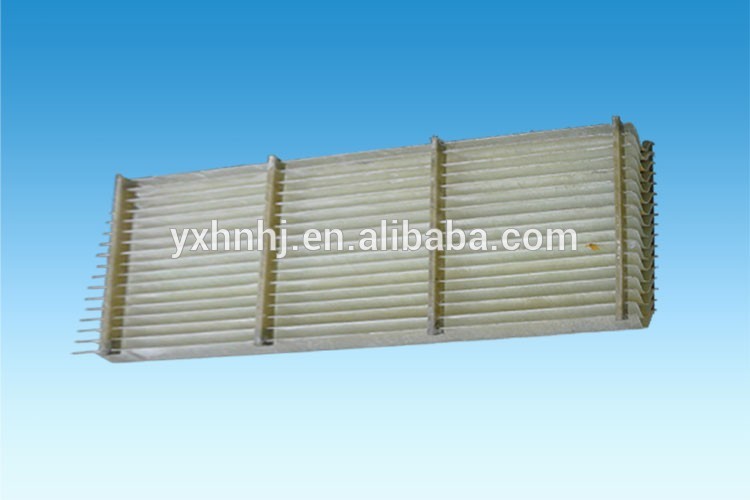

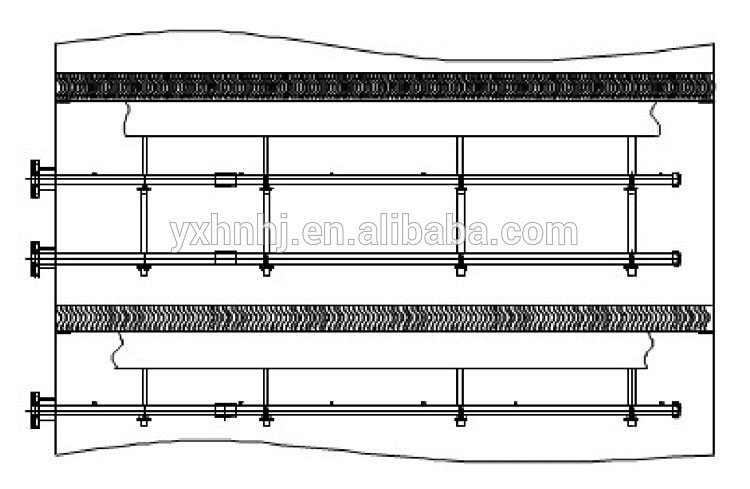

The flat blade system consists of two parallel blades of drift eliminator and three layers of flushing water pipe. The first layer removes coarse particle fog drops, and the second layer removes fine particle fog drops. Critical separation size of flat plate mist eliminator : 28 to 40 um, 40 mm for first degree, 30 mm for secondary .

Flushing system including: nozzle, pipeline and pipe clamp, etc. Water pipe of drift eliminator is made by anti-corrosive carbon steel or stainless steel. The dimension of nozzle is 316L. The layout form of flushing pipe is the top and bottom side of the first-degree drift eliminator and bottom side of the second-degree mist eliminator. 200% flushing water spray overlap rate ensures demister run with low resistance.

The plate type drift eliminator is crossly made by corrugated shape blade and steel plate. It is installed on top of tower and perpendicular to structure of flue gas. There are two layers of design: first and second level. Flue gas imports into mist layer vertically. Steel plate and the blade are connected with hotgas welding and thermofussion welding. The distance ranges between steel plates is between 520-660mm, which changes according to the distance of channel. The distance between blades is: 40 mm for first level, 25 mm for second level. The general channel span is 1850 mm. The interval between beams is 2185 mm. Three layers of flushing : two upward in the front of the drift eliminator, one downward on the back of demister. The interval between two-stage mist eliminator ranges between 1800-1950mm. Washing up and down two layers of first-degree mist eliminator, washing up one layer of second- degree drift eliminator. No need to wash the back part.(as shown)

Q: Are you trading company or manufacturer ?

A: We are manufacturer.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is one month if the goods are not in stock, it is not only according to the quantity, but also how big the project it is.

Q: Do you provide samples ? is it free or extra ?

A: No, we manufacture equipment which is specially designed for specific customers.

Q: What is your terms of payment ?

A: 30% T/T in advance ,60% before shippment. Another 10% after the device have operated for one month.

Product Categories : Mist Eliminator

Premium Related Products